Iterative hardware product development

When an innovative product idea emerges, one of the first question coming to mind is: what do we start with?

Beyond the user experience we want to deliver, the market expectations and the idea of the product we want to accomplish, as if it wasn’t enough to occupy our mind, building a drone hardware adds its share of trade-offs. For example: longer battery life requires a bigger battery, which makes the drone heavier, which eventually may lead to less autonomy, and a product that doesn’t fit the target market usage.

With many interrogations and choices to be made on the architecture and no answers in the horizon, there are 2 approaches to product design and development:

- Waterfall : start with a big idea and define all the steps to get there hoping it will come together in the end,

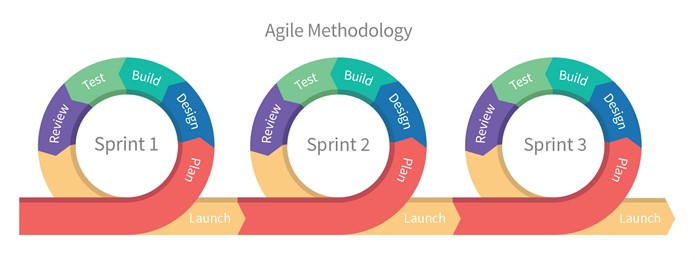

- Agile : very popular in software development, the principle are rapid prototyping and regular validation of overall project until it meets expectations by working on its pieces and always having something to show/test.

The typical agile methodology is illustrated by the following picture :

The aim is not to get the perfect product at the first iteration but to get experience in a short time, unlock those interrogations and choices to learn and continuously modify and adapt the architecture.

This approach imposes to use a modular architecture, just like a puzzle, every submodule can be modified without impacting other parts. Only the interfaces need to stay compatible. For example, the arms should be able to evolve independently of the body of the drone.

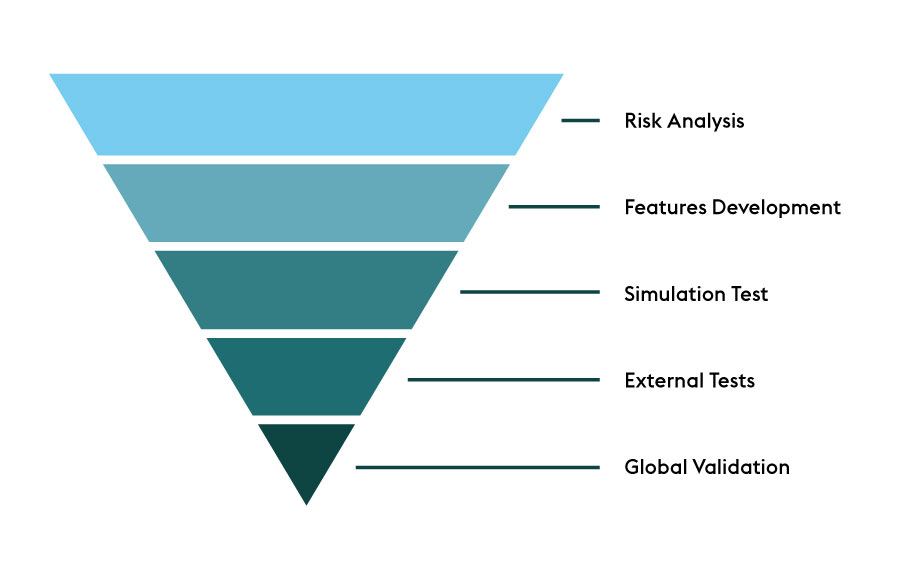

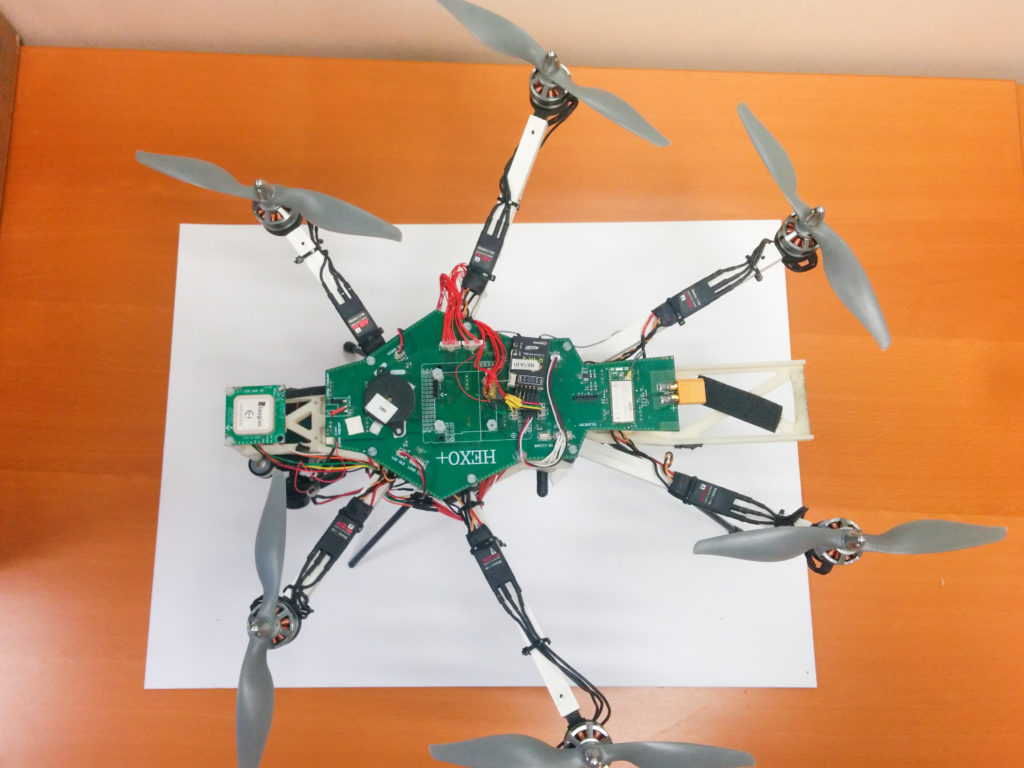

Based on this methodology, we’ve developed the hardware for the project Hexo+ as follows:

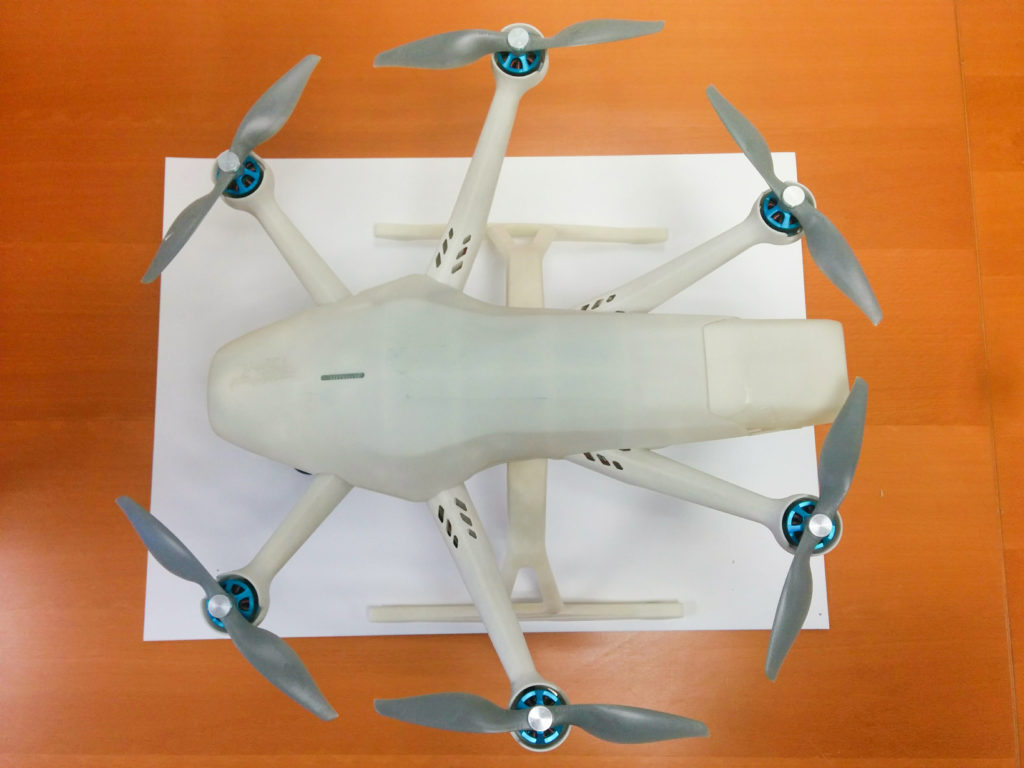

First iteration (1 month) – Alpha:

we wanted to validate the motors repartition, their characteristics to be able to carry the camera and an estimated weight of the drone.

Second iteration (2 month) – Dragonfly:

Once the motors were chosen, smallest battery and drone dimension roughly known, we wanted to validate that if we move the camera in the front, we don’t see anymore the propellers in the video. We need then to move the battery pack on the back.

We validated also the first iteration of our electronics in this design: position of the GPS, interference between high currents and magnetometer.

Third iteration (3.5 month) – EVT0:

For this iteration, due to manufacturing, weight and design constraints, we restarted the design and every mechanical parts quite from scratch. We kept the big numbers validated in the 2 first iterations.

We validated also the second iteration of our electronics in this design: industrialization and testability, certifications (CEM, FCC,…)

After the EVT0, we didn’t change anymore the global architecture of the HEXO+ but we have done 2 more iterations (EVT1 and EVT2). For EVT1 and EVT2 we entered more in the details and modified slightly some few parts such as the arms to make them lighter or the feet to make them stronger.

After EVT2, everything was ready and validated to start the mass production.

Final product:

It took us 12 months from the first iteration to distribution of the 3500 units we first produced. By using an iterative process, we have been able to lift many interrogations the sooner, which was for the better. We’ve lifted many challenges very early, and the results are here: our shipped units have a very low defective rate, which means, more happy customers!

Newsletter

Don’t miss our news !

Our solutions

CLOVER

Autonomous Indoor Drone

Data capture,

inspection and monitoring

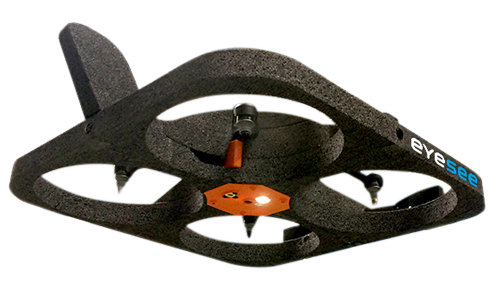

EYESEE

Autonomous inventory drone

Indoor inventory

by barcode reading

APACH

Drone with adaptable payload

Control, inspection, day and night

CROW

Fast and reactive drone

Aerial action with

adaptable payload